Light Engineering Workshops

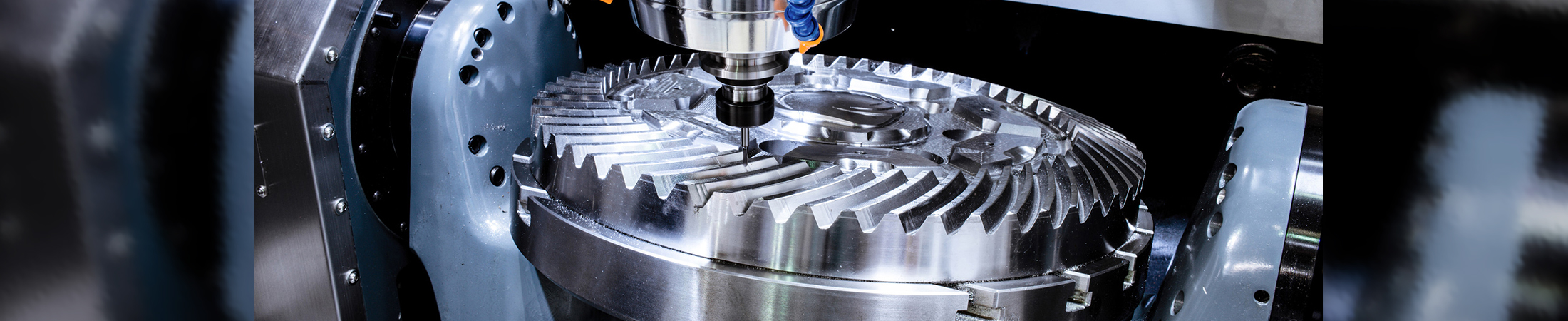

Today the Light Engineering Workshops are located at Katpadi, Puducherry and Tiruchirapalli. It employs persons with disabilities, trained at WORTH Trust’s own technical training centres. They are trained to operate every kind of conventional and CNC machines. CNC machines are installed at the units to produce high precision components to very close tolerances. Other conventional machines in operation include a range of turret lathes, capstan lathes, single spindle automats, milling machines, centreless grinders, thread rolling machines, drilling machines etc. The products manufactured cover a wide spectrum: components for shock absorbers for two and four wheelers, steering parts, brake parts and a host of others. The products are so good and consistent in quality that all of them are used by original equipment manufacturers – both large and medium, both for their domestic and export markets. The fact that some of the customers have been with WORTH Trust for over thirty years, speaks volumes about the quality, timely delivery and reasonable pricing – in short, good business ethics.